diy cerakote oven heating element

Diy cerakote oven heating element. I used a toaster oven at the base.

How To Make A Cerakote Station In Your Garage Part 1 Art Of The Gun

Dec 1 2020 - Step by step details on how to build a cerakote oven on a budget.

. Its also a popular choice for cerakoters. If youre wanting to use a LA2500 with a blower fan addon at temperatures above 375F we strongly recommend a heating element upgrade in order to reach temperatures of up to 500F for the best results. Make a diagram or snap a photo to remember how the wires are attached.

The element and fan are the only two things that will be wired up. I bought two charcoal lighter elements and an adjustable. A pack of 1000 316 diameter x 18 grip steel pop rivets should get you through the oven build with a few left over.

Mount the junction box in an easy to access location on the exterior. Powder Coating Oven Controller Kit 240V 30A 7200W KIT-PCO103 44 out of 5 stars. Ad Appliance Repairs Made Easy - Free Video Tutorials for DIY Repairs.

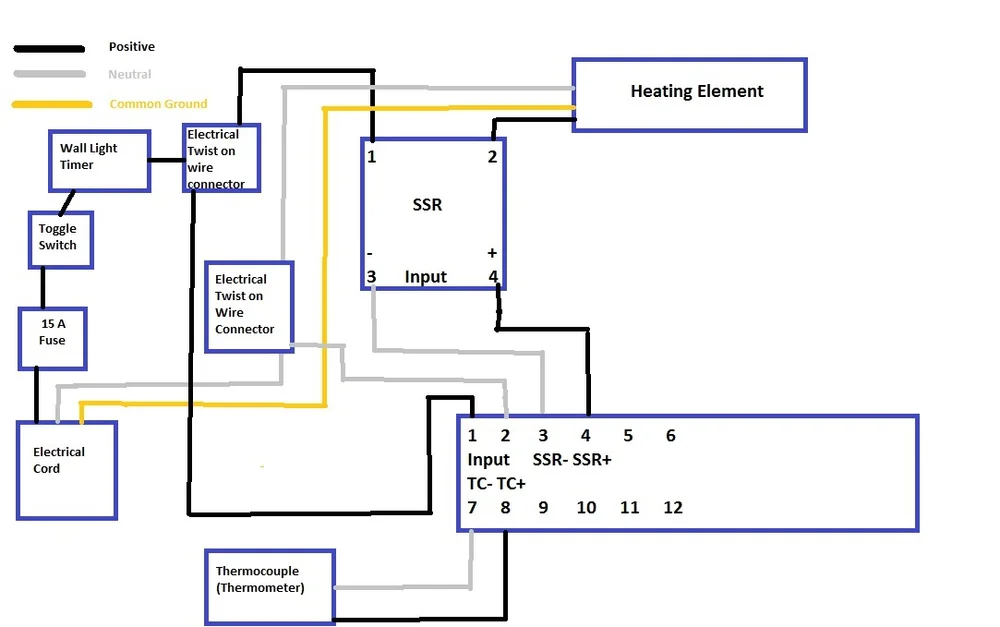

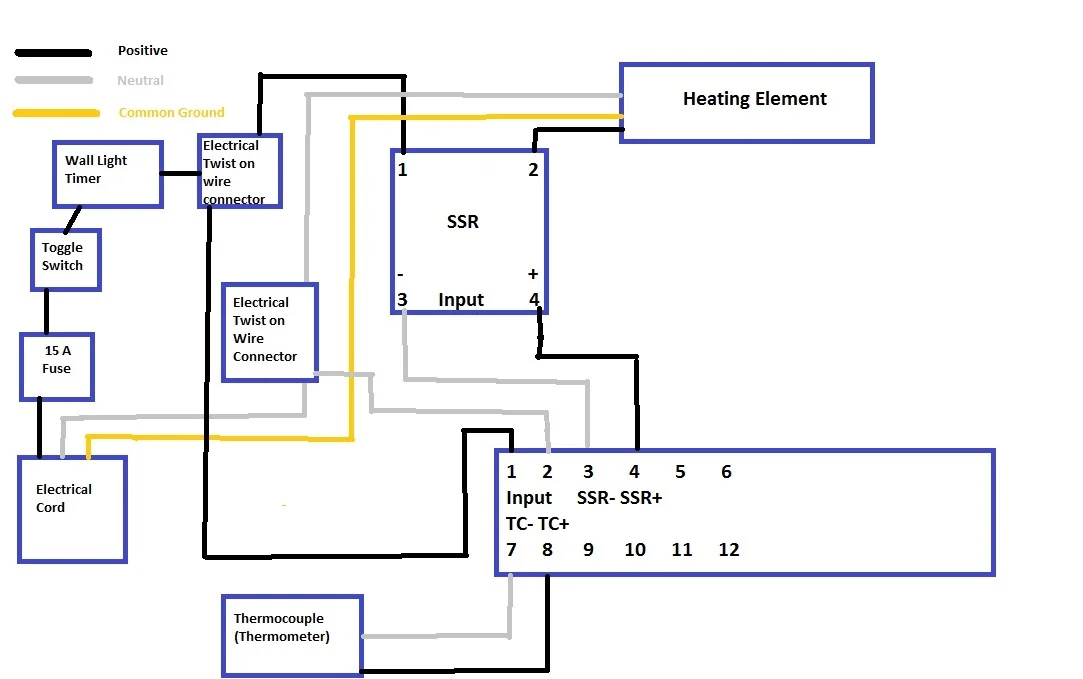

Aluminum Faced 750 Foam Board Lockable. Solid State Relay SSR Heat Sink. Ceramic heating elements and resistance heating.

Remove the screws that hold the wires to the prongs on the element. Buy OEM Parts Guaranteed To Fit Your Oven Model. I just built a small Curing Oven for Cerakote Duracote Paint ect.

Used pop rivets to attach the flange to the oven. Optional wire and wiring fitting kit is available here. I built a wood box and lined it with sheet metal.

Or coils ribbons and wires of an alloy embedded in a plate of ceramic insulation. Order Your Appliance Parts Today. The hottest temp is the gassing out phase prior to application at 300 degrees so were not talking about really high heat.

To apply Cerakote we ordered the following items from Brownells. I used a heat gun to provide the air and heat I installed a BBQ thermometer in the lid and cut a hole for the barrel of the heat gun. PID controller with build-in timer function.

Start date jan 11 2021. I wanted to insulate the cabinet for efficiency and to keep the heat inside so I decided to use drywall. KeyserSoSay Collector of Hobbies and Vestigial Skills Edgewood New Mexico.

What I am saying is that when you take the element out of the small space of a toaster oven and place it inside of a much larger enclosure like a 6 foot tall locker I would think you would have heating problems. Wiring diagram and other manuals are provided. From what I read about cerakote moving air is not needed so an oven should work.

The creator used a 22g08mm galvanized metal sheet a 72c50 72mm subassembly thickness metal u channel 4mm rivets and a few other tools and materials. Whole Series of Options. KG guncoat recommends using moving air at 300degrees to cure the finish.

DIY Full Size Cerakote Curing Oven Picture Info Heavy Greetings group Im here today to discuss the fabrication of a full sized Cerakote curing oven. All totaled about 20000. Make sure this fits by entering your model number.

I started to build an oven and I even bought the supplies just have not got around to building it yet. I lined the base near the element with heat resistant insulation and then used a couple layers of the reflective insulation for the upper part. Diy cerakote oven heating element.

Mount the heating element in the bottom of the cabinet. Use the wiring diagram that comes with your components to ensure everything is. With the 3 500W elements it gets to target temp in about 10 minutes.

Simple insulation board from Home Depot 8 hardwired burner smoker thermometer and all thread for hanging parts. Diy cerakote oven heating element. Accurately measure each panel and place a piece of insulation.

If it were to use 1500 watt heating elements it would then require 533 heating elements. Perfect for DIY cerakoting projects or starting a cerakoting side hustle. You would need to either use 5 or 6 heating elements to heat the oven.

I simply drilled two holes in the bracket that came on the heating element and mounted it directly to the floor of the cabinet. DIY curing oven for your cerakote gun kote or powder cote projects. Cheap And Extremely Effective A Diy Oven For Diy Powder Coating Wood Drying Acrylics And Plastic You Name Powder Coating Oven Powder Coating.

If you just need to do the occasional piece this is a cheap option. It uses 4 2000W heating elements to accomplish this which pull a total of 3333 amps at steady state there is a higher current draw when the heating elements are turned on. Most Cerakote curing is done in a temperature range of 150 to 250 degrees.

45 out of 5 stars. 2 1000w Coils Element Shield. So I took the heating elements out of the toaster oven I bought at the thrift store and custom made a housing for them out of sheet metal.

Initially it climbs fast. Much like what was already posted. It has aluminum on the front a green.

Cerakote oven cure kit. I also purchased all the electronics but learned this combo held at 255 degrees without it. My DIY oven was to take a 4 drawer filing cabinet cut it in half front to back and use the remaining sheet metal to create a door.

For the final 10C it slows down so that it doesnt overshoot the target. Designed for electric heater up to 240V 30A 7200W. JEGS Bench Top Powder Coating Oven 1600 Watt 120 Volt Operates Up To 450 Degrees Fahrenheit 3 Foot Cord Built-In 60 Minute Timer.

The elements cycle on and off during the cure process so its within tolerance for the entire time. DIY kit for powder coating oven control panel. Discussion in The Tool Shed started by KeyserSoSay Mar 20 2018.

I am not disagreeing. 6142013 60239 am est i know a few of you have built them. Step 3 Mount the junction box heating element and thermocouple to the cerkote oven.

After all it is much easier to heat a 1 and a half foot square piece to 450 degrees than a 6 foot tall one. Diy-powder Coatcerakote Curing Oven. I used an old toaster oven and took some snips and cut out a circle in the top to fit a duct flange.

Put on enough duct for a long gun wrapped it in duct wrap and put on a cover. 1 offer from 39999. Be extremely careful to reattach them the same way.

2500B best starter Option. Ill need to run multiple batches for. Ships from Local Depo.

Jun 21 2013. Ad Search by Model. How to make a Curing Oven for Cerakote Duracote Paint ruebarb.

Yes HiLow Individual Element Switching. You would need enough fireproof insulation to compensate for the heat loss. 525 F Audible Alarms.

Gunsmithing Best Idea For Making Cheap Diy Cerkote Oven Practical Machinist Largest Manufacturing Technology Forum On The Web

Diy Cerakote Oven Cerakote Oven Diy Powder Coating Diy

Diy Refinishing Oven Page 4 The Gun Counter

Home Made Curing Oven How To Northeastshooters Com Forums

My Homemade Cerakote Oven Youtube

How To Make A Cerakote Station In Your Garage Part 1 Art Of The Gun

How To Make A Cerakote Station In Your Garage Part 1 Art Of The Gun

Cerakote Powdercoat Curing Oven Problem Solved The Hobby Machinist

How To Make A Cerakote Station In Your Garage Part 1 Art Of The Gun

Diy Curing Finishing Oven 3 3 Youtube

Diy Refinishing Oven Page 3 The Gun Counter

Diy Full Size Cerakote Curing Oven Picture Info Heavy Calguns Net

Diy Full Size Cerakote Curing Oven Picture Info Heavy Calguns Net

Diy Full Size Cerakote Curing Oven Picture Info Heavy Calguns Net

Paint Curing Oven Oklahoma Shooters

How To Make A Cerakote Station In Your Garage Part 1 Art Of The Gun

Homemade Powdercoating Oven Powder Coating Oven Powdercoating Powder Coating Diy

How To Make A Cerakote Station In Your Garage Part 1 Art Of The Gun